Manuals:MBPlusFblV5:Setupmenu H: Difference between revisions

Shornstein (talk | contribs) No edit summary |

Shornstein (talk | contribs) No edit summary |

||

| (One intermediate revision by the same user not shown) | |||

| Line 2: | Line 2: | ||

<!--T:1--> | <!--T:1--> | ||

{{DISPLAYTITLE:SETUP MENU H - Servo trim|noerror}} | {{DISPLAYTITLE:SETUP MENU H - Servo trim|noerror}} | ||

{{TOC_MBPlusV5|Manuals:MBPlusFblV5:Setupmenu_G/en|Manuals:MBPlusFblV5:Setupmenu_I/en}} | {{TOC_MBPlusV5|Manuals:MBPlusFblV5:Setupmenu_G/en|Manuals:MBPlusFblV5:Setupmenu_I/en|SETUPMENU}} | ||

__TOC__ | __TOC__ | ||

<br /> | <br /> | ||

<!--T:2--> | <!--T:2--> | ||

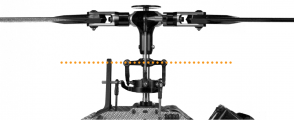

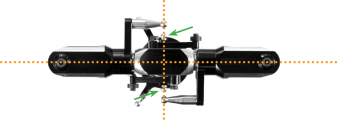

At SETUP MENU point H we trim the servo center positions so that each servo horn forms an exact 90 degrees angle with the adjustment linkage. This is necessary as usually you will not be able to attach the servo horns in exact center position to the servo. '''After all servos have been trimmed do not proceed to the next menu point yet.''' | At SETUP MENU point H we trim the servo center positions so that each servo horn forms an exact 90 degrees angle with the adjustment linkage. This is necessary as usually you will not be able to attach the servo horns in exact center position to the servo. '''After all servos have been trimmed do not proceed to the next menu point yet.''' After trimming adjust the linkage rods according to your helicopter's manual, so the rotorhead system is set up neutral and allows to have equal movements in all directions. For this the swashplate should be at the midpoint and perpendicular to the main shaft and the rotor blades should have 0 degrees of pitch. Always work this out from bottom (servos) to top (blade grips).<br /> | ||

<br /> | |||

In case your helicopter has a non-DFC rotor head with adjustable swashplate driver also don‘t forget to level and phase the swashplate driver in the correct way. At 0 degrees of pitch the swash driver arms must be horizontal and the linkage balls of the blade grips must be perpendicular to the spindle shaft.<br /> | |||

<br /> | <br /> | ||

{| | {| | ||

| Line 18: | Line 20: | ||

=Adjustment on the device= <!--T:3--> | =Adjustment on the device= <!--T:3--> | ||

Initially when the trimming is 0 on all servos the Status LED will be off. Attach the servo horns on the servos at their true center position, so that you get roughly equal throws to both direction. Mount the servo horns so that they form | Initially when the trimming is 0 on all servos the Status LED will be off. Attach the servo horns on the servos at their true center position, so that you get roughly equal throws to both direction. Mount the servo horns so that they form a 90 degrees angle to the linkage rod as close as possible. Then in the next step you electronically fine trim every single servo‘s center position, as usually mounting the servo horn at exact 90 degrees will not work out perfectly depending on the servo‘s gear train and the servo horn.<br /> | ||

<br /> | <br /> | ||

By tapping the aileron | By tapping the '''stick for aileron''' you can '''select one servo after another'''. Every color of the Status-LED is corresponding to a specific servo channel that is indicating its selection by a short up and down move. Use the '''rudder stick''' to change the '''servo trimming/adjust the center position'''. You can switch back and forth between the servos as often as you need.<br /> | ||

<br /> | <br /> | ||

{|cellpadding="4" cellspacing="0" border="1" | {|cellpadding="4" cellspacing="0" border="1" | ||

| Line 35: | Line 37: | ||

| style="color:white; background: linear-gradient(to right, #FF3300, black, #0066FF)" | red/blue || CH7 – elevator servo(2) (90° eCCPM only) | | style="color:white; background: linear-gradient(to right, #FF3300, black, #0066FF)" | red/blue || CH7 – elevator servo(2) (90° eCCPM only) | ||

|}<br /> | |}<br /> | ||

<br /> | <br /> | ||

<br /> | <br /> | ||

Latest revision as of 09:21, 19 July 2018

At SETUP MENU point H we trim the servo center positions so that each servo horn forms an exact 90 degrees angle with the adjustment linkage. This is necessary as usually you will not be able to attach the servo horns in exact center position to the servo. After all servos have been trimmed do not proceed to the next menu point yet. After trimming adjust the linkage rods according to your helicopter's manual, so the rotorhead system is set up neutral and allows to have equal movements in all directions. For this the swashplate should be at the midpoint and perpendicular to the main shaft and the rotor blades should have 0 degrees of pitch. Always work this out from bottom (servos) to top (blade grips).

In case your helicopter has a non-DFC rotor head with adjustable swashplate driver also don‘t forget to level and phase the swashplate driver in the correct way. At 0 degrees of pitch the swash driver arms must be horizontal and the linkage balls of the blade grips must be perpendicular to the spindle shaft.

|

|

Adjustment on the device

Initially when the trimming is 0 on all servos the Status LED will be off. Attach the servo horns on the servos at their true center position, so that you get roughly equal throws to both direction. Mount the servo horns so that they form a 90 degrees angle to the linkage rod as close as possible. Then in the next step you electronically fine trim every single servo‘s center position, as usually mounting the servo horn at exact 90 degrees will not work out perfectly depending on the servo‘s gear train and the servo horn.

By tapping the stick for aileron you can select one servo after another. Every color of the Status-LED is corresponding to a specific servo channel that is indicating its selection by a short up and down move. Use the rudder stick to change the servo trimming/adjust the center position. You can switch back and forth between the servos as often as you need.

| Status-LED | Servo trim |

| off | all zero |

| purple | CH1 – elevator servo |

| red | CH2 – aileron(1) servo |

| blue | CH3 – aileron(2) / pitch servo (mCCPM) |

| red/blue | CH7 – elevator servo(2) (90° eCCPM only) |

Setup with StudioXm

When the servo trim screen appears, for your reference the servos will briefly move up and down once one after another in the given order CH1 to CH3 (CH7) so you can identify them easily. Trim each servo using the + and - buttons so that the servo horn forms an exact 90 degrees angle with the linkage rod. Then make the mechanical adjustment for the linkages as described above if necessary.

File:SetupHm.png